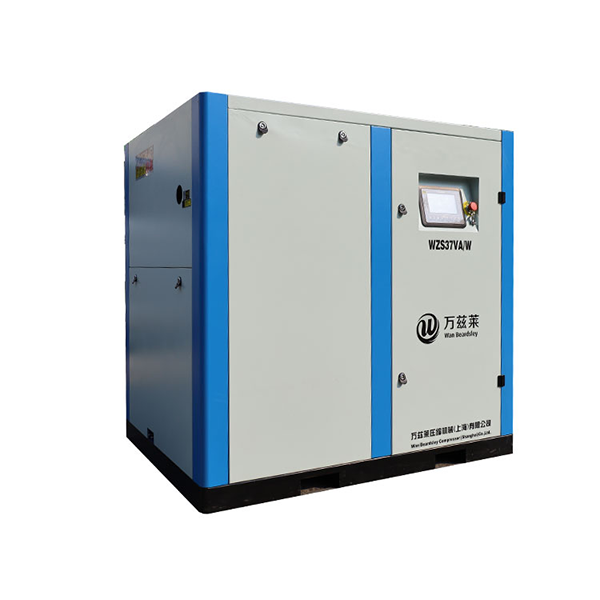

Water-injected Oil-free Air Compressors

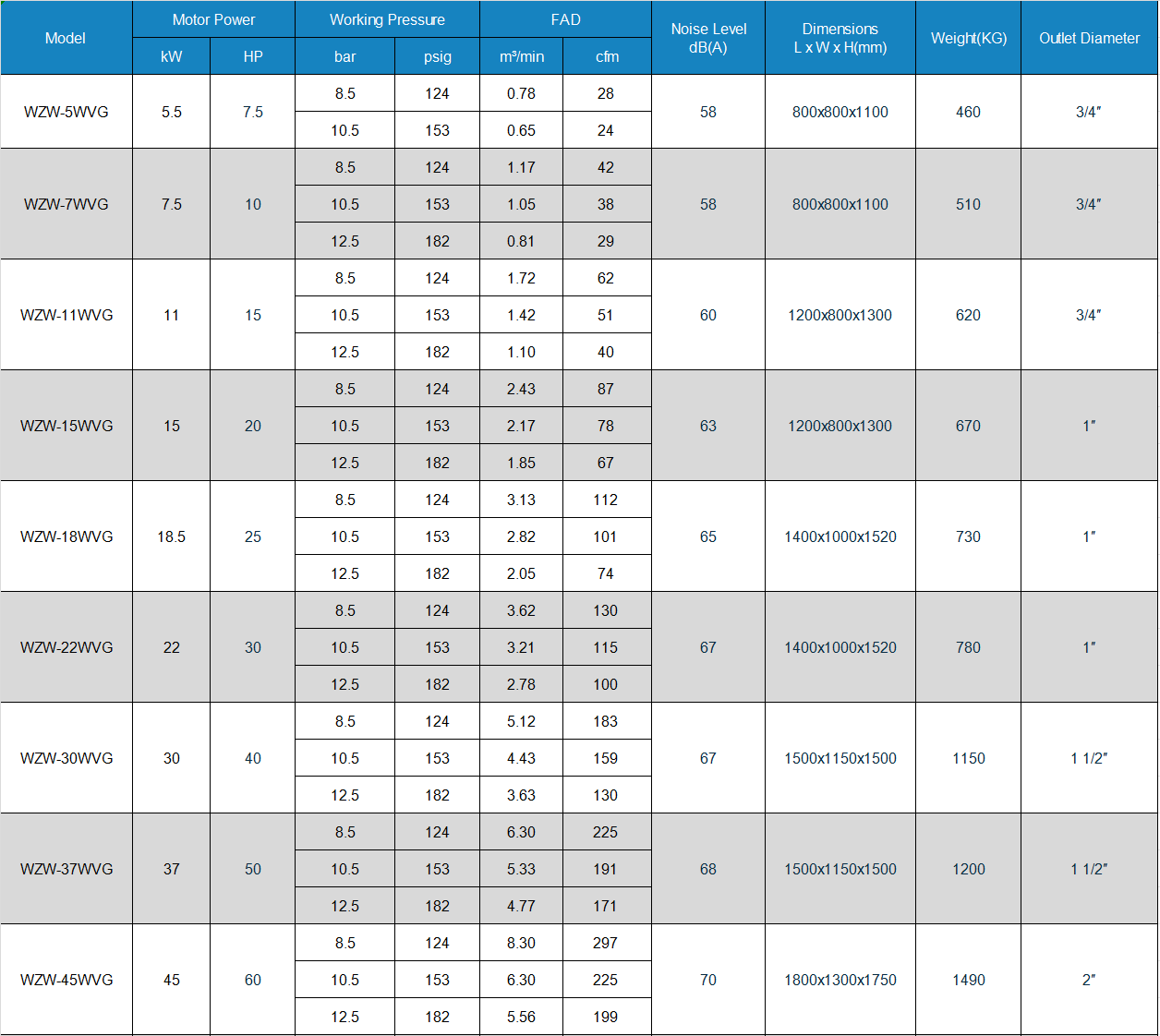

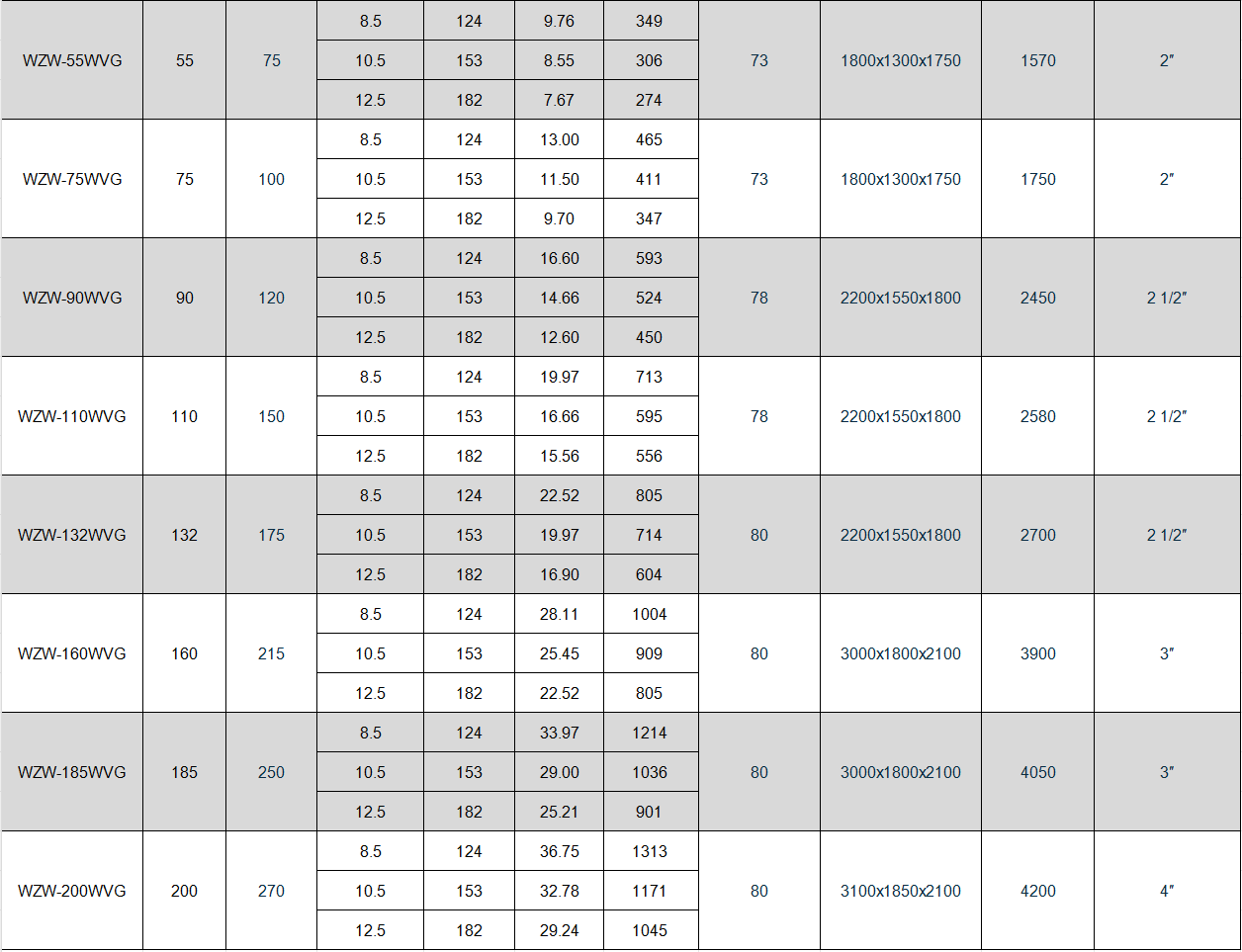

Power: 5.5~250KW

Air flow: 0.65~44.78m³/min

Working pressure: 0.8~1.25Mpa

- Description

- Specifications

- FAQs

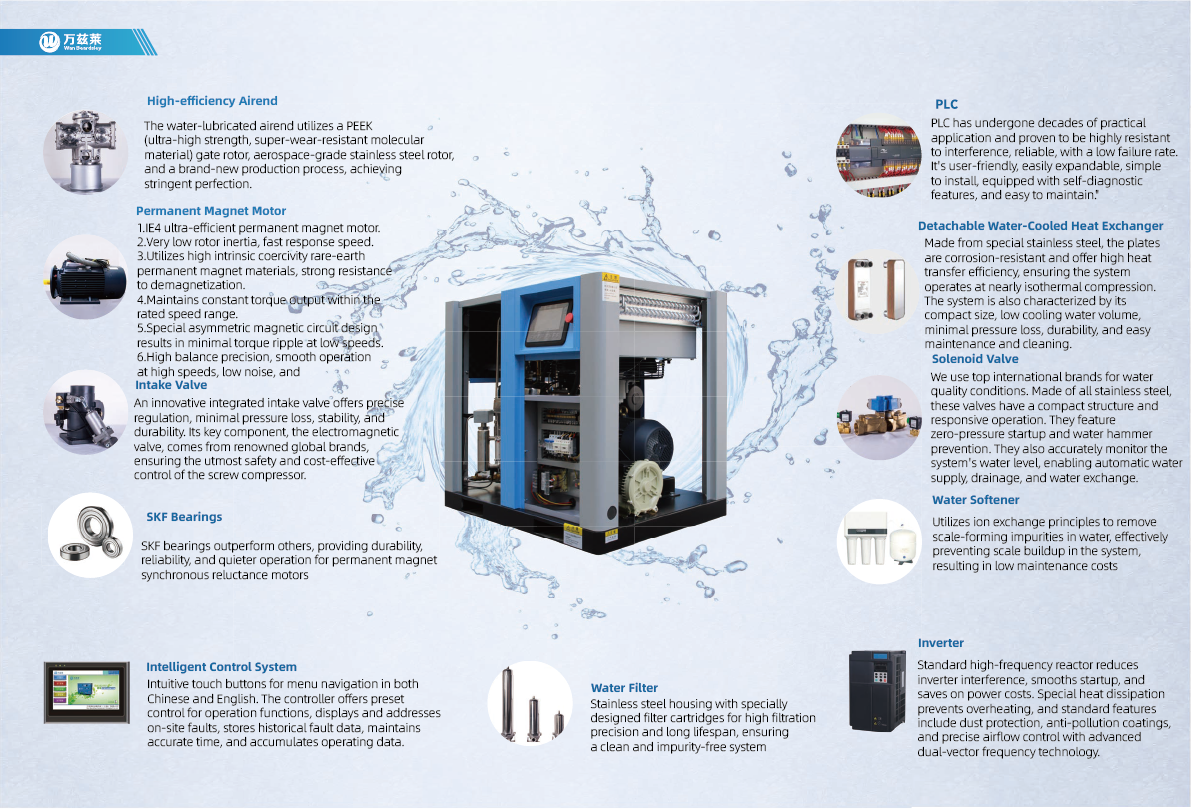

Q : What are the advantages of using a water-injected oil-free air compressor?

A : The primary advantage is that it produces oil-free and contaminant-free compressed air, making it suitable for applications where oil contamination is a concern. It also reduces environmental impact and maintenance costs.Q : What applications are suitable for water-injected oil-free air compressors?

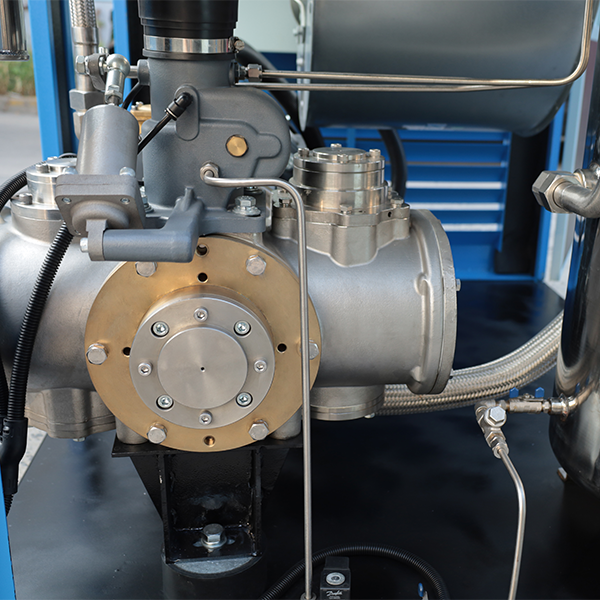

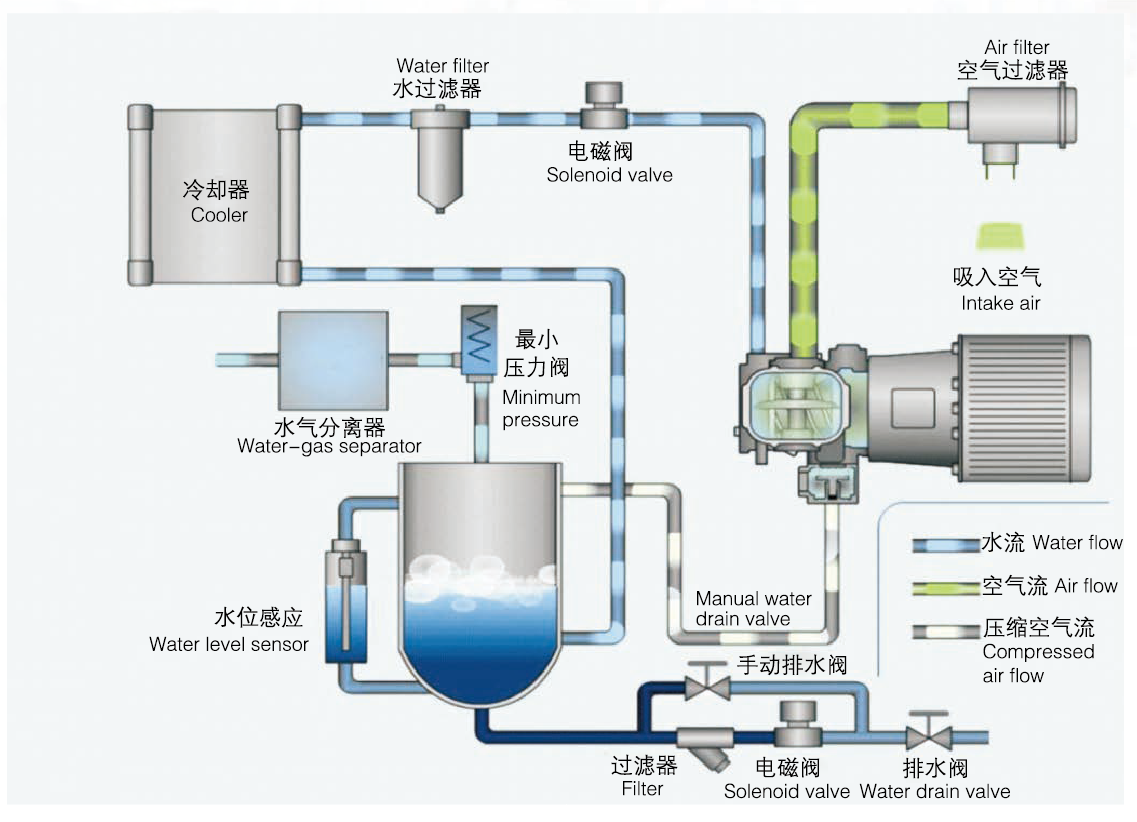

A : These compressors are commonly used in industries where clean and oil-free air is critical, such as pharmaceuticals, food and beverage, electronics manufacturing, and laboratories.Q : How does the water lubrication and cooling system work?

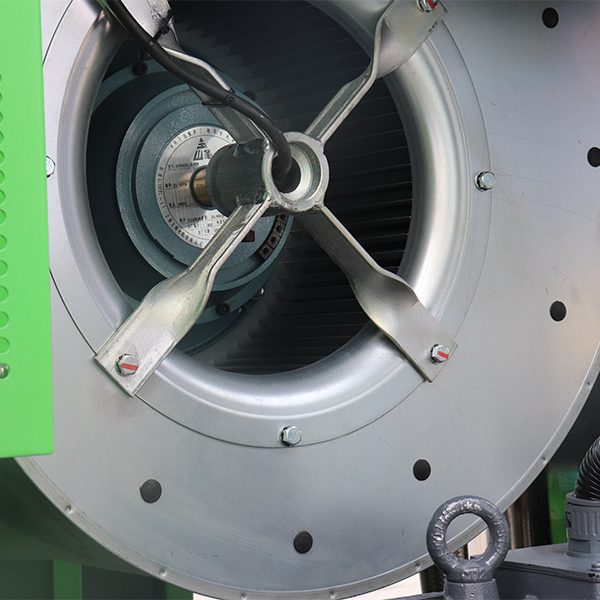

A : Water is injected into the compression chamber to serve as a lubricant and coolant. It also helps remove heat generated during compression, ensuring efficient operation.Q : Is the water used in the compressor recirculated or discharged?

A : In most cases, the water is recirculated within the compressor's closed-loop system to conserve water and maintain its cooling and lubricating properties.Q : Do water-injected oil-free air compressors require regular maintenance?

A : Yes, regular maintenance is necessary to ensure the proper functioning of the compressor. Maintenance typically includes water quality checks, filter replacements, and periodic inspections.