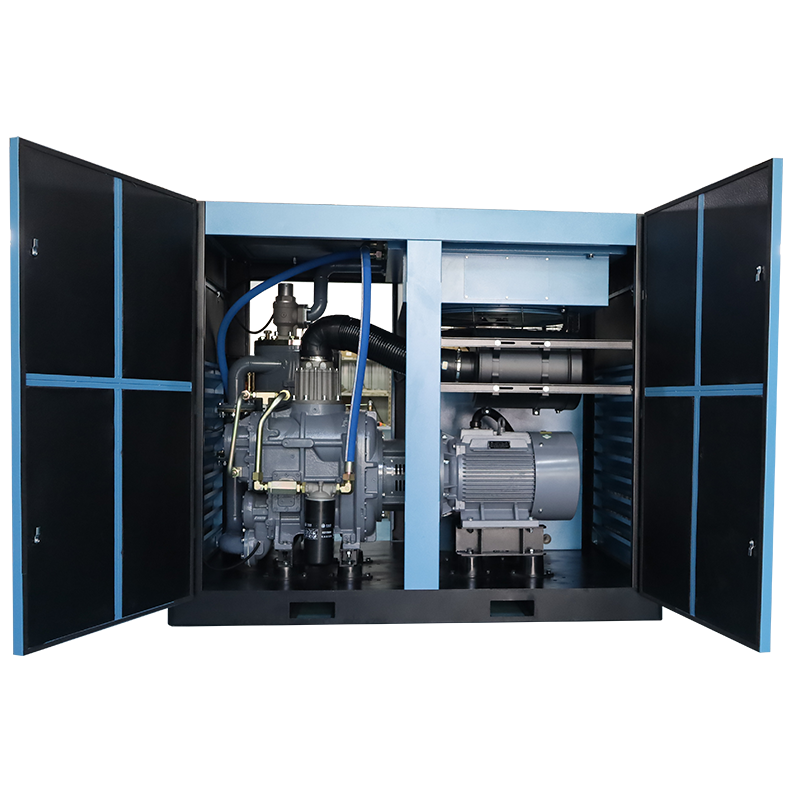

Permanent Magnetic VSD Two-stage Screw Air Compressors

Power: 22~250kw

Air flow: 3.2~61m3/min

Maximum working pressure: 1.25Mpa

- Description

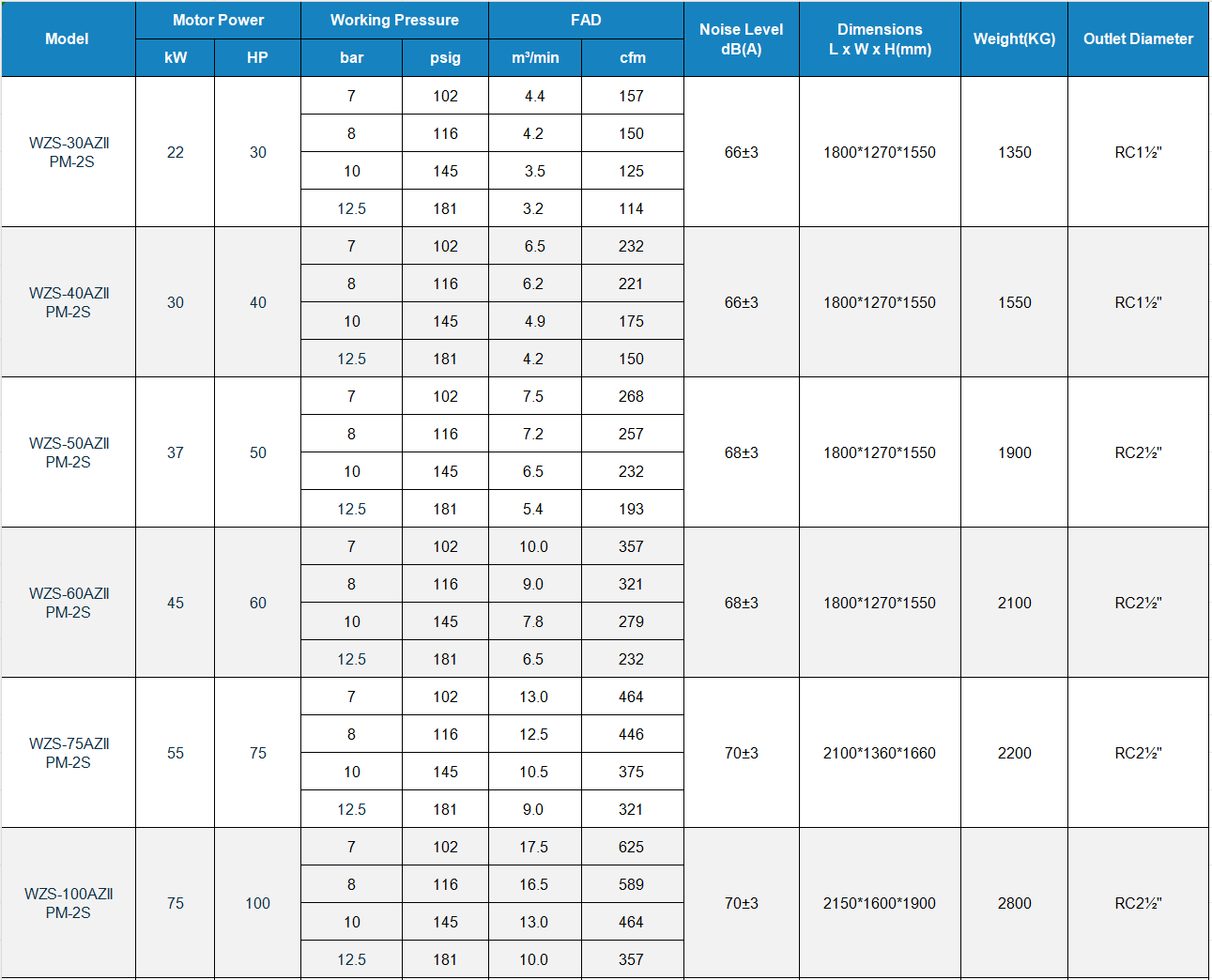

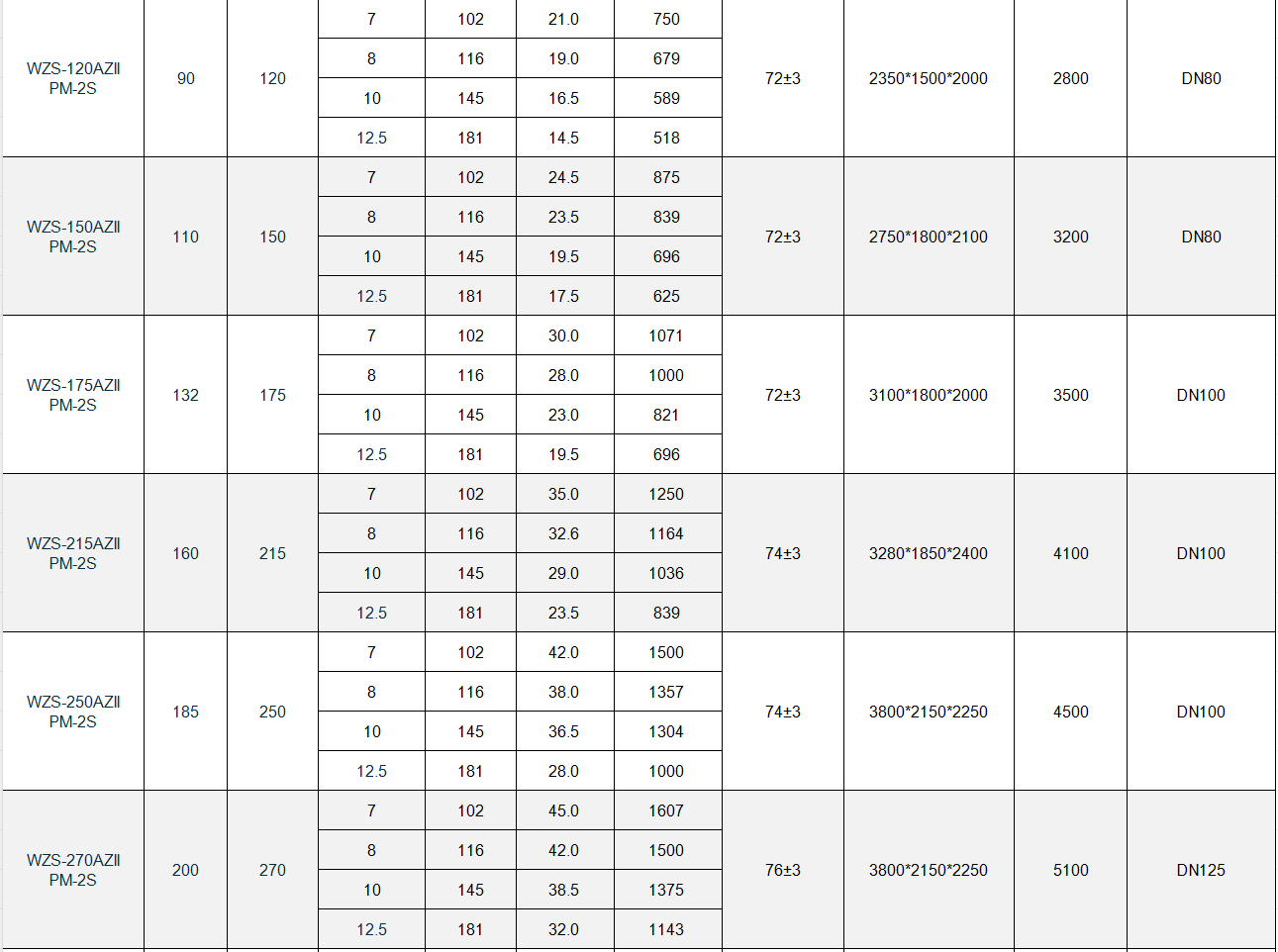

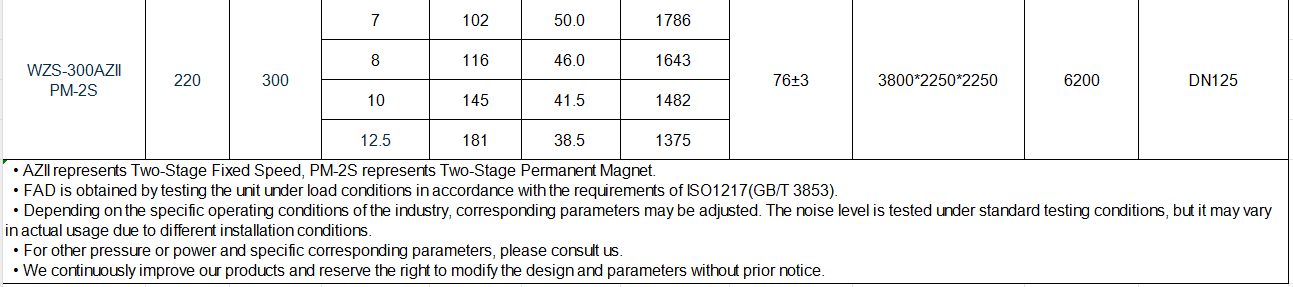

- Specifications

- Video

- FAQs

Q : What is a two-stage screw air compressor?

A : A two-stage screw air compressor is a type of air compressor that compresses air in two stages to achieve higher pressure levels. It consists of two screw elements or stages that work in tandem to increase the air pressure.Q : What are the advantages of a two-stage screw air compressor over a single-stage compressor?

A : Two-stage screw air compressors can achieve higher pressures, making them suitable for applications that require high-pressure air. They are more energy-efficient and offer better performance in demanding industrial settings.Q : How does a two-stage screw air compressor work?

A : In the first stage, air is compressed by the first screw element to an intermediate pressure. Then, in the second stage, the compressed air from the first stage is further compressed to the desired higher pressure level by the second screw element.Q : What are the typical applications for two-stage screw air compressors?

A : Two-stage screw air compressors are commonly used in industries such as manufacturing, automotive, aerospace, and petrochemicals, where high-pressure air is needed for various processes, including pneumatic tools, automation, and control systems.