The Differences Between Oil-Free Screw Air Compressors and Oil-Injected Screw Compressors, and Their Working Principle Structure Diagrams

Twin-Screw Air Compressor

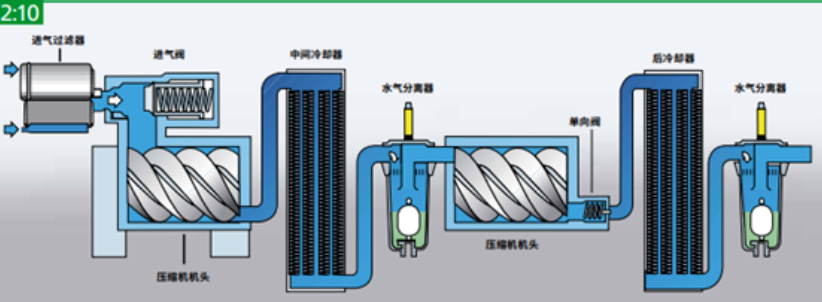

Oil-Free Screw Air Compressor

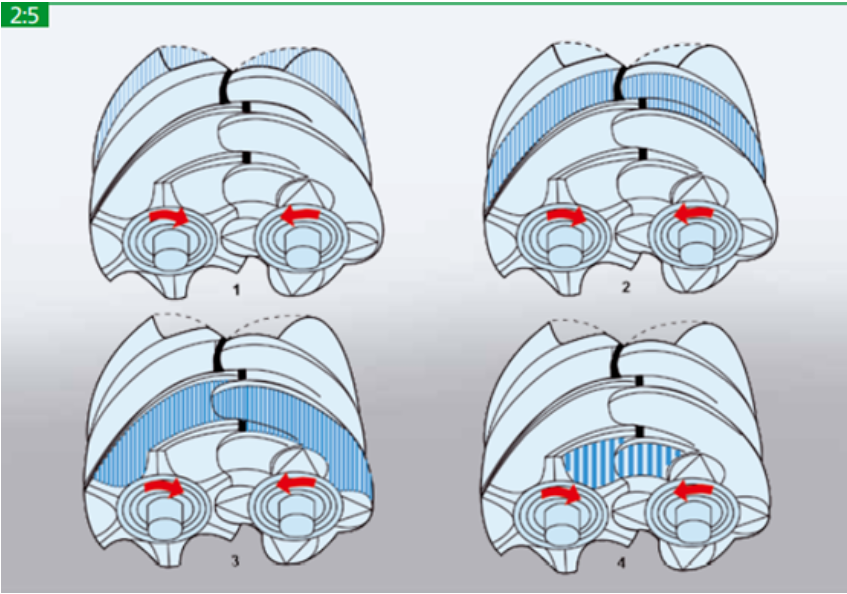

The first twin-screw air compressor had symmetrical rotor profiles and did not use any coolant inside the compression chamber. These are known as oil-free or dry screw air compressors. Modern high-speed oil-free screw air compressors have non-symmetric rotor configurations, which significantly increase energy efficiency by reducing internal leaks.

External gears are the most commonly used means of synchronizing the rotors to rotate in opposite directions. Since the rotors cannot contact each other or the housing, lubrication is not required inside the compression chamber. Therefore, the compressed air remains completely oil-free. Both the rotors and the housing need to be precisely manufactured to minimize leakage from the compression side to the intake side. The built-in compression ratio is limited by the maximum pressure difference between the intake and exhaust ports. This is why oil-free screw air compressors are generally designed for staged compression and incorporate internal cooling to achieve higher pressures.

Compression Diagram for Twin-Screw Air Compressor

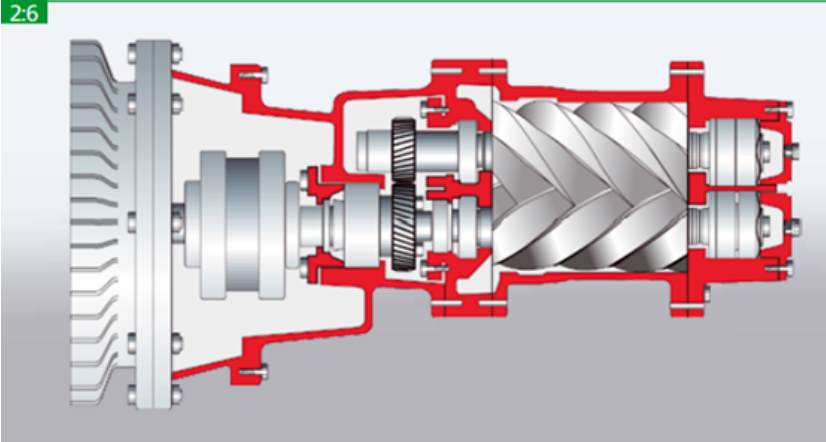

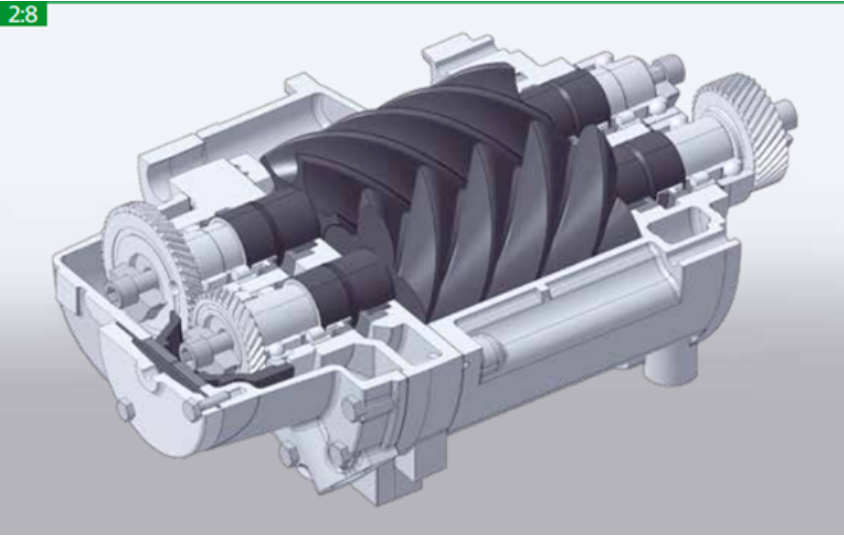

The Typical Oil-Lubricated Screw Air Compressor Airend and Drive

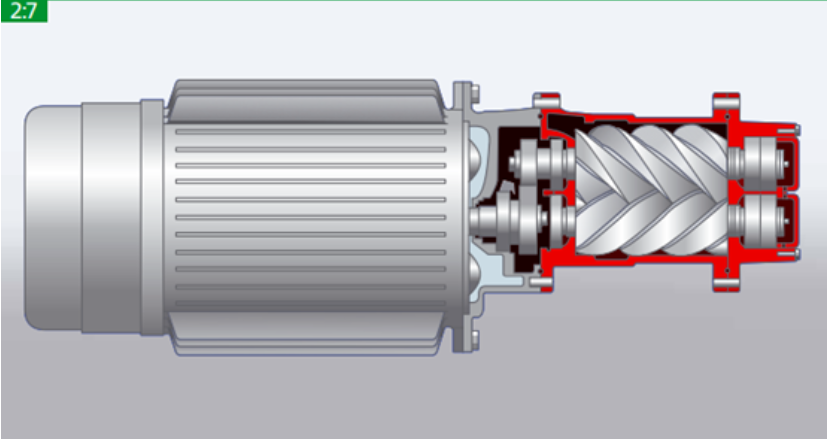

Modern Oil-Injected Screw Air Compressor with Drive Unit

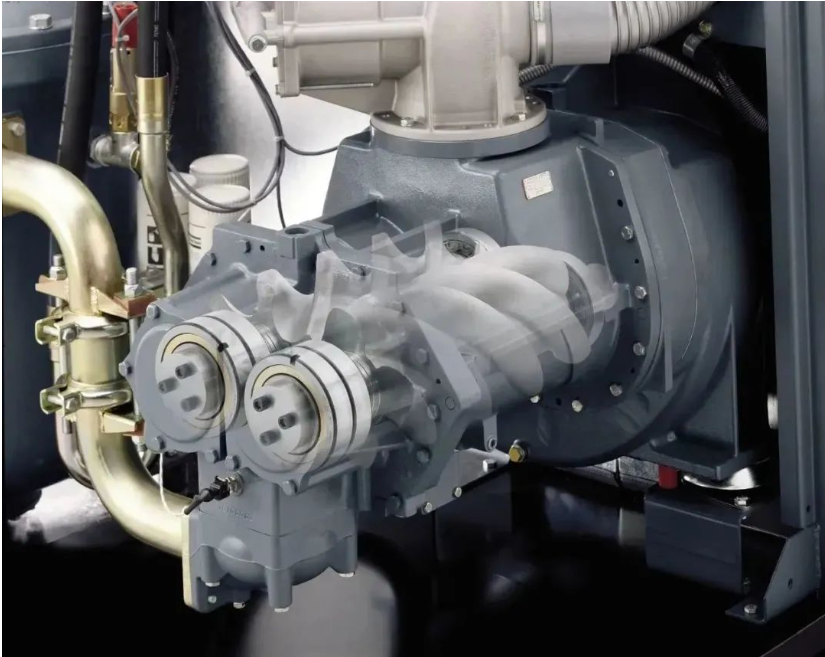

The Head of an Oil-Free Screw Air Compressor with Liquid-Cooled Rotor Housing, Equipped with Air and Oil Seals at Both Ends, and a Set of Synchronized Gears to Maintain a Minimal Gap between Rotors

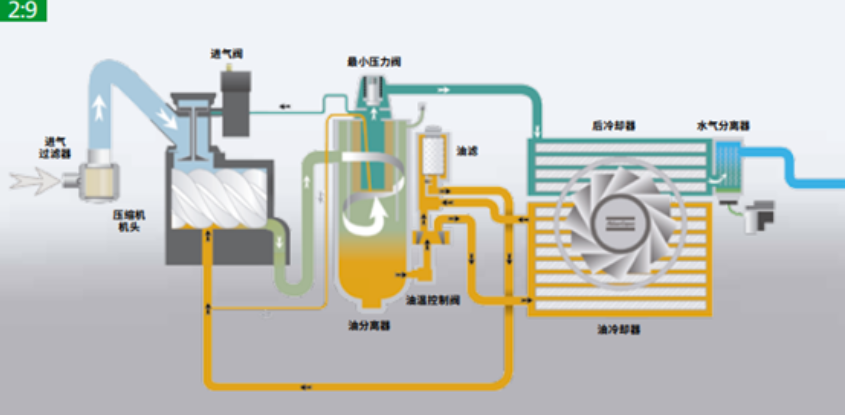

In Liquid-Injected Screw Air Compressors

Liquid enters the compression chamber and often reaches the air compressor's bearings. Its function is to cool and lubricate the moving parts of the air compressor, cool the air being compressed internally, and reduce leaks back into the intake duct.

Currently, lubricating oil is the most common injected liquid because of its excellent lubricating and sealing properties. However, other liquids like water or polymers are also used as injected fluids. Liquid-injected screw air compressor components can be applied to achieve high compression ratios, and a single stage of compression is often sufficient, allowing pressures to reach 14 bar or even 17 bar, although this may reduce energy efficiency.

Flow Diagram of an Oil-Injected Screw Air Compressor

Flow Diagram of an Oil-Free Screw Air Compressor